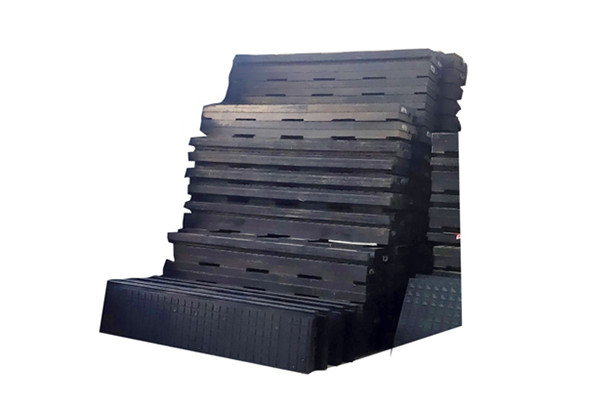

The railway rubber pad has the function of a railway track shock absorber, providing longitudinal resistance to rail displacement, compensating for dynamic loads on sleepers, and also has an electrical insulation function.

Kingrail Parts has a professional HDPE/EVA/rubber pad production line. The elastic rail pads we produce can meet UIC, AREMA, TB and other standards. We can also customize rubber rail pads as per our customers' specifications and requirements.

Specification:

| Raw Material | Rubber,EVA,TPEE,HDPE |

| Standard | UIC, AREMA, TB/T2626-95 |

| Application | 43kg/m, 50kg/m, 60kg/m, 75kg/m,115RE, UIC54, UIC60, S49 |

| Model number | 43-7-7, 43-10-7, 50-7-9, 50-10-9, 60-10-17, 60-12-17 |

| Operating temperature | -50~70 degrees |

| Certificate | MSDS, ROHS, REACH |

| Notes | They should be stored in a clean, ventilated place. Don’t be direct sunlight, keep away from the heat source and chemical reagent. Don’t touch the oil, organic solvent and other chemicals. Banned exposure. |

Rubber pad mechanical properties:

Stiffness: 90-130KN

Tensile strength before aging: ≥12.5Mpa

Elongation before aging: ≥250%

Melting point: 72-80℃

Electronic resistance: ≥106Ω

EVA rail pad mechanical properties:

Density: 0.95-0.98 g/m3

Tensile strength: ≥15Mpa

Elongation: ≤500%

Melting point: 170 – 190 ℃

Insulation resistance: ≥10,000,000 KΩ

Hardness: ≥90A

HDPE rail pad mechanical properties:

Density: 0.95-0.98 g/cubic meter.

Tensile strength: ≥19Mpa.

Elongation: ≥80%.

Melting point: 170-190℃

Insulation resistance: ≥10,000,000 KΩ

Hardness: ≥98A

Contact us

Please contact us for more information and quotes.

Inquiry Now