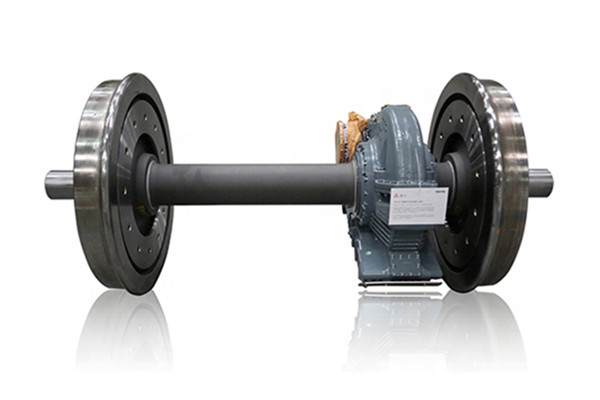

The crane rail wheels are the most important part of the crane traveling system. They carry the weight of the crane and guide the crane to move.

As a professional wheel manufacturer, we can manufacture a variety of high-quality crane rail wheels of different diameters or materials for your choice.

Crane Rail Wheels Features:

1. Fast Turn Around Times

2. Flange Wear, Fracture and Pitting resistant

3. Long service life and precise design

Crane Rail Wheel Manufacturing Process:

Billet Steel Review→ Cutting→ Heating→ Forging→ Heat Treatment→ Sampling Test→ Rough Machining→ Semi-Finish Machining→ Finish Machining→Hardness test→Static unbalance test → Ultrasonic Inspection→ Magnetic Particle Testing→ Packing

Types of Crane Rail Wheels:

According to different standards, crane wheels can be divided into single flange and double flange crane wheels, cast and forged crane wheels, etc.

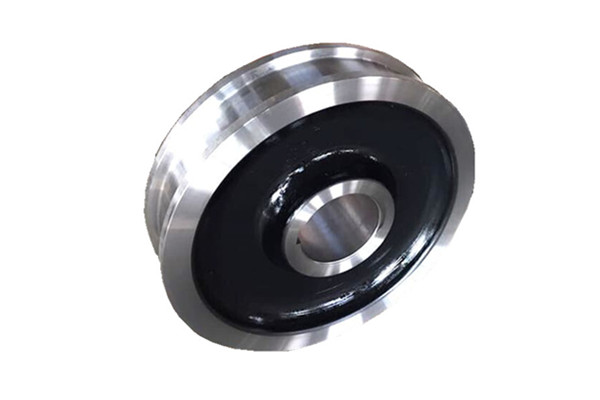

1.Single Flange Crane Wheels:

1). Single flange crane wheels are used in conjunction with bridge cranes and gantry cranes.

2). The height of the rim is 20mm~25mm. Use ZG340-640 cast steel or ZG-50SiMn low alloy steel.

3). The quenching depth of the wheel pattern is not less than 20mm.

4). The rolling surface hardness of ZG340-640 cast steel wheels is 300~350HB; ZG50SiMn has a hardness of 420~480HB.

5). The mechanical properties, precision and roughness of the material meet the requirements of JB/T 6392-2008.

2. Double Flange Crane Wheels:

1). Double flange crane wheels are used in conjunction with bridge type heavy-duty cranes and gantry cranes.

2). The height of the rim is 25mm~30mm. Use ZG340-640 cast steel or ZG-50SiMn low alloy steel.

3). The quenching depth of the wheel pattern is not less than 20mm.

4). The hardness of the rolling surface of ZG340-640 cast steel wheels is 300~350HB;

5). ZG-50SiMn, hardness 420~480HB.

6). The mechanical properties, precision and roughness of the material meet the requirements of JB/T 6392-2008.

Inquiry Now