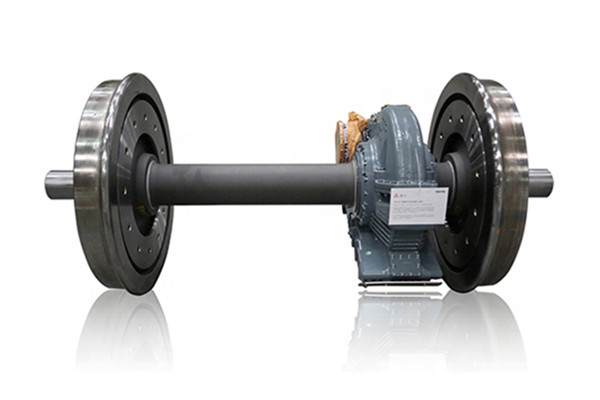

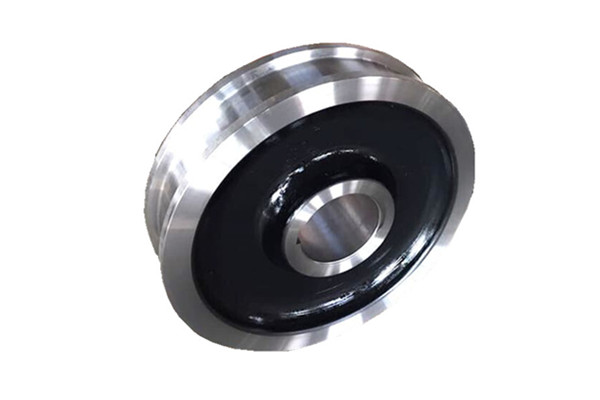

Kingrail Parts products mainly include hundreds of six varieties of train wheel, wheel tyre, wheel center, forging ring parts, disk assembly, forging pieces.

Kingrail Parts is the main wheel supplier of railway wagons, passenger trains, and locomotives. You can also create high -speed train wheels with heavy -duty locomotive wheels and a speed of 250km/h.

Our train wheel production quality assurance system has passed the ISO9000: 2000 quality system and authoritative certification issued by AAR issued by the North American Railway Commission.

Specification:

|

Dimension Range of Railway Wheels |

|||||||

|

Outside Diameter Ø D, mm |

Inside Diameter Ø D1, ØD2 mm |

Width of Rim H mm |

Diameter of Hub Ø d mm |

Height of hub L mm |

Diameter of Hole in Hub Ød0 mm |

Thickness of Disk t1, t2 mm |

Mass WG kg |

|

650-1269 |

600-1100 |

95-160 |

185-500 |

90-405 |

60-200 |

15-80 |

165-1050 |

Kingrail Parts provides casting wheels and forging wheels, all of which are produced in accordance with international standards:

* AAR M-107/M-208 wheels, carbon steel specifications

* EN 13262 Railway Application Wheel -Product Requirements

* BS 5892-3 Traction and trailer overall wheel specification

* JIS E5402-2 railway locomotive and vehicle solid steel wheel

* TB/T 2817 Railway freight car for forging steel solid wheel technical specifications

Manufacturing process:

Ingot→Cold cutting→Heating furnace with ignot section→9000 tons of press→Wheel rolling mill→5000 tons of press→Heat treatment furnace→Heat treatment tank→Sand blasting→Inspection→Machining→Inspection→Transportation

Contact us to get more information and offer.

Inquiry Now