The elastic crane rail pad allows the rail to move and rotate slightly. When the rails run on rubber pads - known as flexible rail mounting - it helps to distribute forces more evenly between the crane wheels and the rails, and between the rails and the rail mounting surface.

Kingrail Parts offers two types of pads for continuous rail and non-continuous installations. Our crane rail pad are made according to E-type, SKL, KPO, NablaPR, Russia, fast, UIC, BS, JIS and other standards.

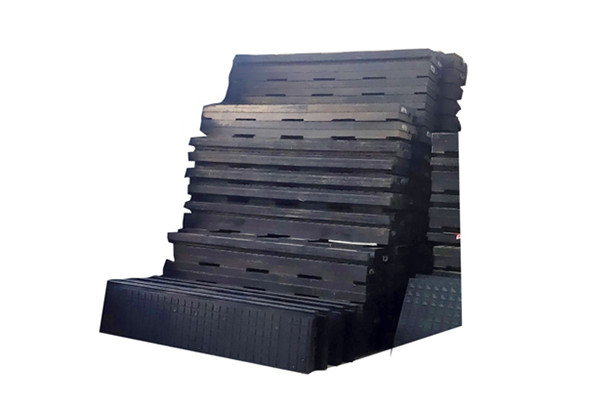

Types of Our Crane Rail Pad

1. The elastic discontinuous rubber backing plate is specially designed for discontinuous rail foundation.

2. The elastic continuous rubber pad is specially designed for the continuous rail foundation.

Flexible rails have many significant advantages, not just noise reduction and vibration reduction. In addition, elastic rubber pads compensate for any unevenness in the rail or steel supports, thereby distributing wheel loads over a larger area, reducing load concentration and fatigue at the support structure. The groove design on the surface of the continuous rubber pad results in a nonlinear load deflection characteristic that controls the rail bending stress.

Another significant advantage is the effective prevention of frictional corrosion between the rail and the steel structure. The standard elastic continuous rubber backing plate is 7mm thick, and the width generally does not exceed the width of the bottom of the track.

Function of Crane Rail Pad:

1.Kingrail Parts rubber pad can be used for any crane or railway track. Mounted on the bottom of the rail, the same width allows the adjustable clamps to fit snugly on the bottom of the rail.

2. The rubber pads greatly reduce the force on the crane beam or beam

3. Use rubber pads to reduce the risk of fatigue failure in support structures

4. The rubber pads make the rail only rotate slightly, the crane wheel presses the force on the rail a little, and distributes the force evenly in all areas of the rail head.

5. The rubber pads eliminate the metal-to-metal impact between the rail and the steel pad. Therefore, the wear and corrosion between the rail and the steel tie plate are greatly reduced. This is very meaningful for outdoor installations or environments with oily, damp, etc.

6. The elastic non-continuous rubber pad and the reinforced continuous rubber pad have been tested, and the compressive strength is 5 times greater than the maximum load of the crane.

Contact us

Please contact us for more information and quotations.

Inquiry Now