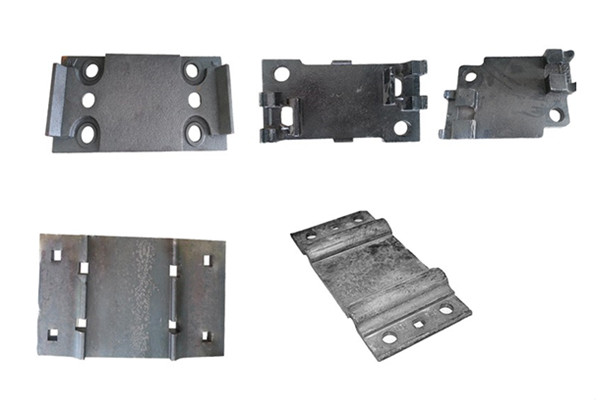

The rail tie plate, also known as rail iron tie plate, railway casting tie plate, railway base plate, is fixed between the rail and the sleepers, and is one of the important components in the rail structure, which plays a role in damping the wheel-rail power system. Our tie plates have good vibration damping performance, impact resistance and long service life.

Kingrail Parts can provide sleeper plates for ordinary railways, high-speed railways, and urban railways according to customer requirements. Our tie plates follow AREMA, UIC, BS and other standards.

Specification

| Model | Application | Material | Unit Weight | Export Destination |

|---|---|---|---|---|

| 115RE Tie plate | AREMA 115RE rail |

Q235 or QT400-15 |

10.6kg/pc | USA |

|

132/136RE Tie plate |

AREMA 132RE rail AREMA 136RE rail |

Q235 or QT400-15 |

11-12kg/p | USA |

| 115D Tie plate | AREMA 115D rail |

Q235 or QT400-15 |

28.8kg/pc | USA |

| 100-8B Tie plate | AREMA 100-8B rail |

Q235 or QT400-15 |

26kg/pc | USA |

| S49 Tie plate | S49 rail |

QT450-10 QT400-15 Q235 |

7.57kg/pc |

| Model | Application | Specification | Material | Standard | Unit Weight | Export Destination |

|---|---|---|---|---|---|---|

| TYPE-D | Subway tie plate | 1/4"*8"*19-1/2" | Hot rolled carbon steel |

ASTM-A36 H.R.1020. |

USA | |

| TYPE-19-A | Subway tie plate | 1/4"*8"*19-1/2" | Hot rolled carbon steel |

ASTM-A36 H.R.1020. |

USA | |

| 01-63-14 | Subway tie plate | 20# | 4.53kg/pc | USA | ||

| 01-63-13 | Subway tie plate | 20# | 5.65kg/pc | USA | ||

| Base Plate | GB38kg rail |

Q235 or QT400-15 QT450-10 |

8.5kg/pc |

OEM Service

We can customize rail gauge rods according to customers' specifications and requirementsContact us

Please contact us for more information and quotations.

Inquiry Now