Railway tie plates, also known as railway base plates or sole plates, are made of low -carbon steel, cast iron, wrought iron, or malleable steel, sandwiched between flat feet and wooden sleeper to distribute a larger area of load.

Kingrail Parts can produce railway tie plates of various sizes to meet the installation needs of different size railways.Our tie plates follow AREMA, UIC, BS and other standards.

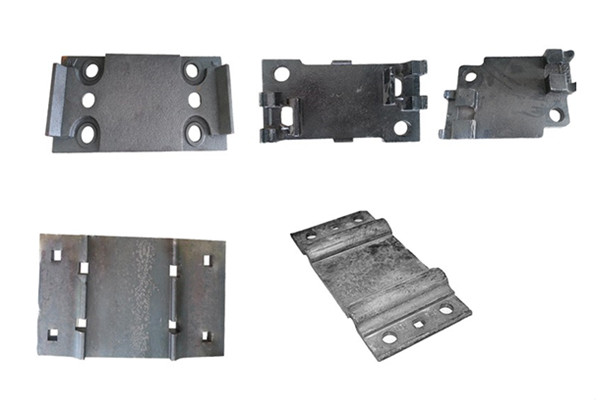

Our Rail Tie Plates

1. Casting Railway Tie Plates

The tie plate can be cast iron or cast steel, depending on the load and rail type. Cast iron can be welded or assembled, depending on the customer's requirements.

Name: Casting rail tie plates

Type: Suitable for rail UIC54, UIC60, 50KG rails, 60kg rails, S49 and order dimensions

Material: QT500-7 or QT450-10 (low-carbon steel or high-carbon steel forging, low-carbon steel S275JR, Q235 and other rolling)

Standard reference: UIC864-6

2. Single Shoulder Railway Tie Plates

For the single shoulder tie plate, the shoulder is designed at the end of the plate. The short end of the plate is placed inside the track, which is why customers always require the width of the bottom of the rail. The rail shoulder tie plates are usually used for rails from 56 pounds to 100 pounds.

3. Double Shoulder Railway Tie Plates

Currently using type is double-shoulder. The older single-shoulder types are suitable for a variety of rail width, and the shoulder is located outside the rail (on -site side).

4. Hook Twin Tie Plates for Railroad

HTTP, full name HOOK TWIN TAIL PLATE, is widely used for turnouts positioned behind the switch bottoms. In order to ensure the distance between the tie, HTTP often uses a single tie. Among them, AREMA is the first domestic and 1 -inch AREMA hook twin tie plate in China.

Different available varieties:

For 3/4 '' ' hook twin tie plate: L23, L27, L31, LR23, LR27, LR31, H23, H27, H31.

For 1 '' ' hook twin tie plate: L29, L33, L37, LR28, LR32, LR36, H29, H33, H37, H41.

In the market, 3/4 '' and 1 '' thick varieties are the most popular in North America. With a modern production line, our workshop is a modern and special workshop. We can produce 1,000 tons of products per year.

In order to ensure the quality of the final product, more than 30 staff members are only prepared for HTTPS, especially the process of punching and hooking. In addition, there is a quality control team, which is responsible for testing and inspection in the process. After years of hard work, we have never received any complaints or dissatisfaction from the buyer.

OEM Service

We can customize rail tie plates according to customers' specifications and requirements

Contact us

Please contact us for more information and quotations.

Inquiry Now