The main function of sole plates is to provide a flat and smooth support surface for the rails.

Sole plates are used to support the rails in cases where the concrete is not strong enough to support the crane rails. Depending on the type of load and rail, sole plates can be made in series or individually. In either case, they are held in place with anchor bolts.

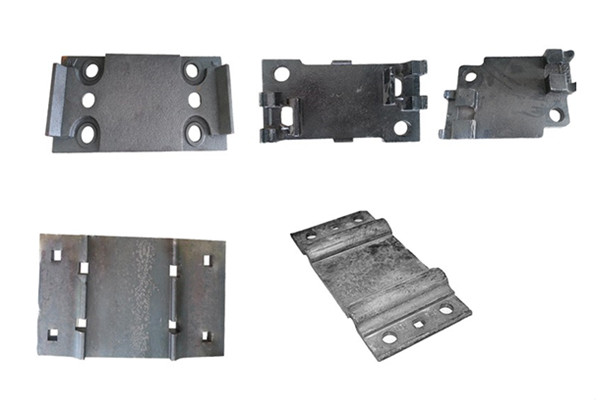

We manufacture the highest quality sole plates for rail mounting, tailored to your requirements.

Our manufacturing process includes:

1. Cut the plate to the correct size

2. Precision drilling of anchor bolts and horizontal bolts

3. Welding weldable clip base and galvanized sheet

4. Surface treatment options can be self-tinting, black, coated and/or hot-dip galvanized.

Types of Railway Sole Plates

1. Single Sole Plates

This is an economical solution for light-duty applications where the rails need to be mounted on a separate concrete base. They can be secured with two or four fixing bolts and come with clips, all bolts and grout

Length: Standard 5980mm.

Width: Varies between 150 and 500 mm.

Thickness: Varies between 12 and 50 mm.

Material: S235JR, S275JR, S355J0.

Anti-corrosion: blackened, coated, hot-dip galvanized, double-sided system.

2. Continuous Sole Plates

Heavier crane rails or heavy duty applications require the strength of the continuous support when the rail is supported on a concrete structure. Continuous sole plates are available with bolt-on or welded clips. However, it is often economical to do more work in the field and use a welded base clip. The design, layout, manufacture and installation of continuous sole plates are not straightforward and require careful planning and execution.

Length: Varies between 150 and 300 mm.

Width: Varies between 150 and 500 mm.

Thickness: Varies between 12 and 50 mm.

Material: S235JR, S275JR, S355J0.

Anti-corrosion: blackened, coated, hot-dip galvanized, double-sided system.

Inquiry Now