Rail track wheels come in three standard forms - they run on chamfered iron called "V-grooves", steel rails called "flanges" or round tubes or pipes called "U-grooves".

Kingrail Parts can produce rail wheels in a wide range of different sizes, materials, bearing types and relative capacities to ensure suitability for most industrial applications.

Our Wheels

V groove Wheels

* Capacities up to 15,000 lbs

* Wheel Diameter: 4" - 10"

* Runs on chamfered iron

* Cast or wrought iron, stainless steel or phenolic

* Supplied with keyway and/or set screws

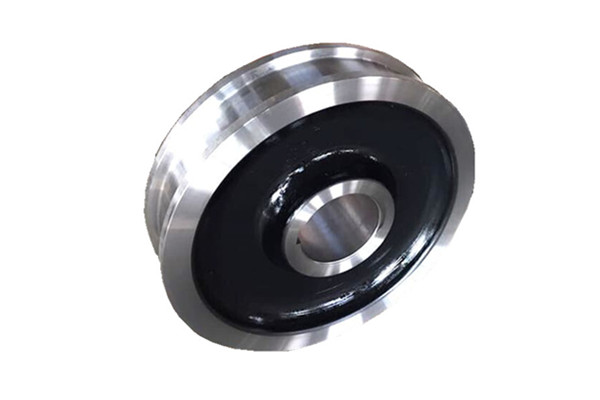

Flange Wheels

* Capacities up to 16,000 lbs.

* Wheel Diameter: 3 1/2" - 15"

* Runs on ASCE track or other types

* Iron or Heavy Duty Nylon

* Custom size and material available

U-shaped Wheels

* Capacities up to 5500 lbs.

* Wheel Diameter: 4" - 10"

* Runs on round pipe or pipe

* Steel, stainless steel or nylon

* Supplied with keyway and/or set screws

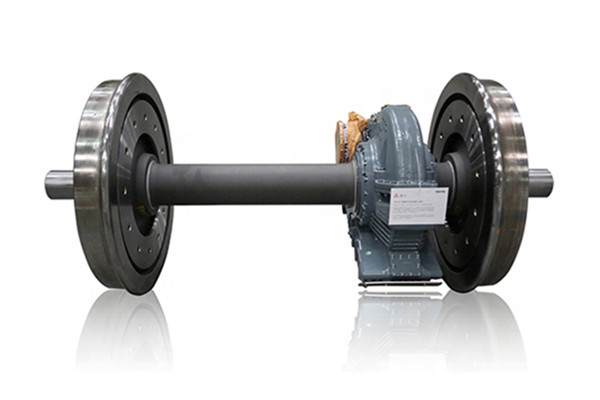

Custom Wheels

When a track is unique or a unique size wheel is required, Kingrail Parts can design and manufacture special wheels to suit almost any industrial application.

Contact us

Please contact us for more information and quotations.

Inquiry Now