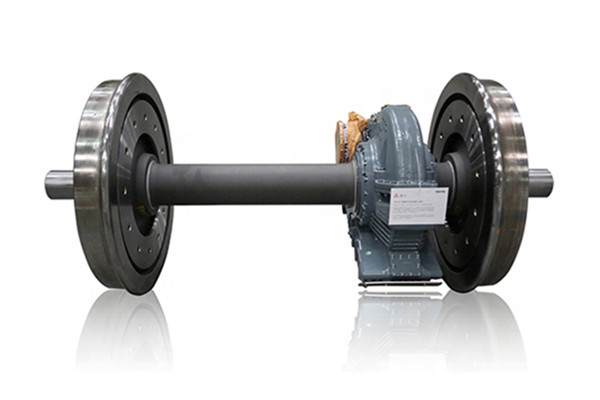

Train wheels and axles are among the most important components of a train. They literally support the safety of railway rolling stock from beneath the floor.

Kingrail Parts can produce train wheels of various sizes to meet the needs of goods transportation and rail traffic.

Our wheels are manufactured to TB/T 2817, AAR M-107/208, BS 5892-3 and EN 13262 standards.

Our wheels

Locomotive wheels

Product: Monobloc wheels, drilled or not. high strength steel. Low stress geometry.

Diameter: 860 mm to 1300 mm.

Grades: Class B, Class B UCS, Class C Mod 2, Class C, Class B HS, ER6, ER7, ER8, ER9, Class T.

Freight wheels

Products: Monobloc wheels, high heat resistance, noise damped or not. Low stress geometry.

Diameter: 680 mm to 1000 mm.

Grades: ER6, ER7, ER8.

High speed wheels

Product: monobloc wheels drilled or not, noise damped or not. Ultra clean steel.

Diameters: 860 mm to 920 mm (and 1092 mm - a world record).

Grades: ER7, ER8, ER9, ER7 ISG, ER8 ISG, ER9 ISG, ER8C, Class B HS.

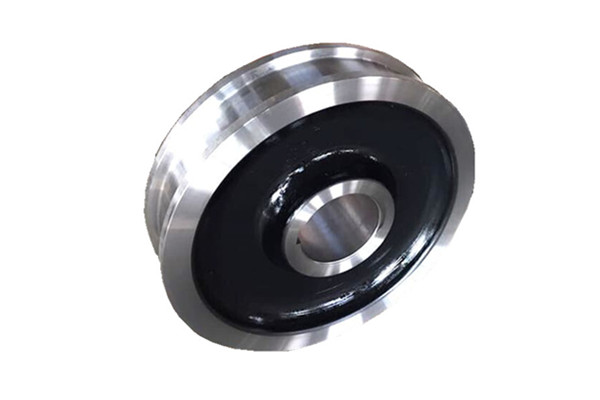

Trams wheels

Products: Multiple-part (resilient) wheel. Low radial stiffness elastomer.

Noise Reduction: Up to 15-20 dB(A) - squealing noise on specific frequencies.

Customized service

We can customize wheels according to your specifications and requirements.

Manufacturing process:

Billet review → cutting → heating → forging → heat treatment → sampling test → rough machining → semi-finishing → finishing → hardness test → static unbalance test → ultrasonic inspection → magnetic particle inspection → packaging.

Contact us

Please contact us for more information and quotations.

Inquiry Now