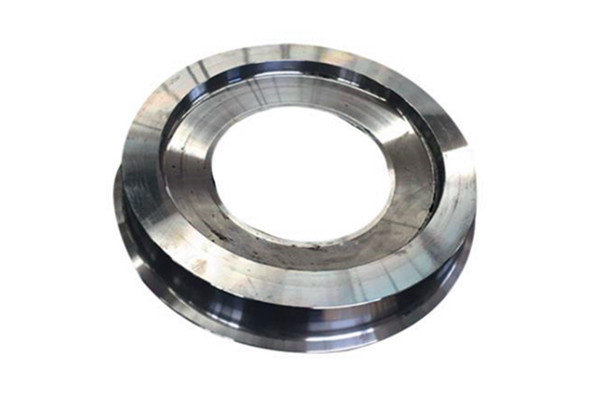

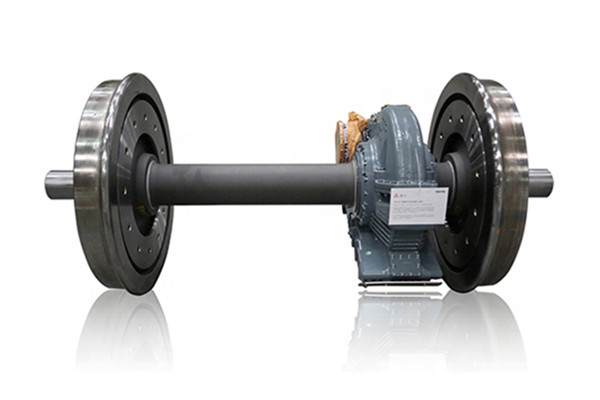

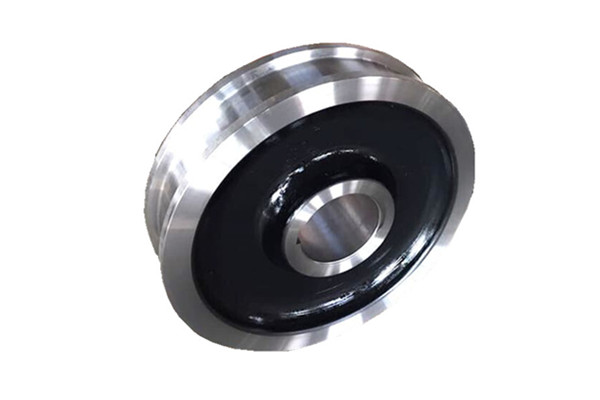

Kingrail Parts provides wheel tyres used by wheels. The tyres are forged and then the tyre drawing is hot rolled.

The size can be controlled as:

* Rough turned wheel tyre

* Finished turned wheel tyre.

Dimensions

Kingrail Parts can provide wheel tyres with a wide range of dimension range. The parameters are as follows:

|

OUTSIDEDIAMETER (MM) |

WIDTHOFTREAD (MM) |

GAUGE (MM) |

MASSWEIGHT (KG) |

AXLELOAD (TON) |

| 780-1700 |

120-150 |

1000-1676 |

176-250 |

12-35 |

Manufacturing specifications:

Kingrail Parts can provide the following specifications and tolerances for customers who order:

British Standard: Part 4 of BS 5892, Railway locomotive Materials -Part 4. Forging and rolling tyre specifications.

European Standard: UIC 810-1 used for the supply of supply technical specifications of rough-rolled non-alloy steel tyres for traction and traction vehicles

European Standard: UIC 810-2 Temperature Direction Vehicle and Trailer Technology Specifications -Tolerance

China Railway Standard: TB/T 1882 railway locomotive and vehicle supply technical specifications for rolling tyres.

China Railway Standard: GB 8602 Railway Railway tyre

ISO 1005-1 Railway locomotive Materials-Part 1: Quality requirements for rough rolling tyres of traction vehicles and traction vehicles.

ISO 1005-2 Railway locomotive Materials-Part 2: tyre, wheel heart and tyre wheel-size, balance and assembly requirements of traction vehicles and traction vehicles.

ASTM A551 railway and fast transportation carbon steel tyre standard specifications

Material grade:

According to our long -term supply experience, Kingrail Parts can provide the following materials for wheel tyres

BS 5892-4: Level B1N, B2N, B3N, B4N, B5E, B6E, B7E

UIC 810: B1N, B2N, B3N, B4B, B5E, B6E

ASTM A551: Class A, AHT level, BHT, BHT, CHT, Class CHT, DHT level

TB/T 1882: LG61

National standard 8602: LG60, LG65

Heat treatment delivery status:

* Hot Rolled status(U)

* Normalizing(N)

* Quenching and Tempering(E)

Test certificate

The test results were confirmed in the certificate 3.1; 3.2 According to the EN 10204 standard, including the following test:

* Chemical analysis

* Stretching test

* Impact Test (KU)

* British hardness (uniformity)

* Ultrasonic detection

* Magnetic particle inspection

* Size and appearance examination

Keep in touch

Contact us to get more information and offer.

Inquiry Now