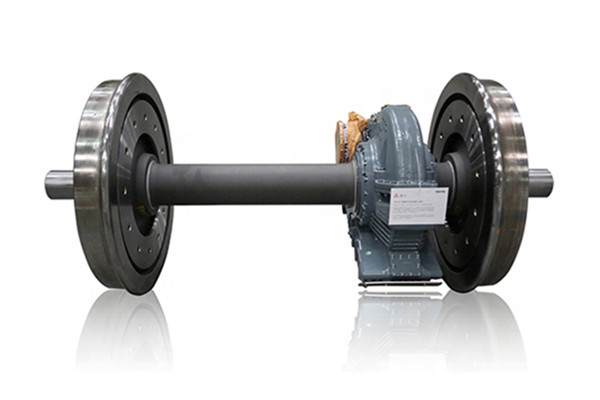

Steel cart wheels are suitable for many industrial applications. Kingrail Parts cart wheels are designed and manufactured to exceed industry standards.

Our heavy duty duty wheels are made of cast or forged steel. They have extremely high strength and durability, thereby minimizing the time required for maintenance and upkeep.

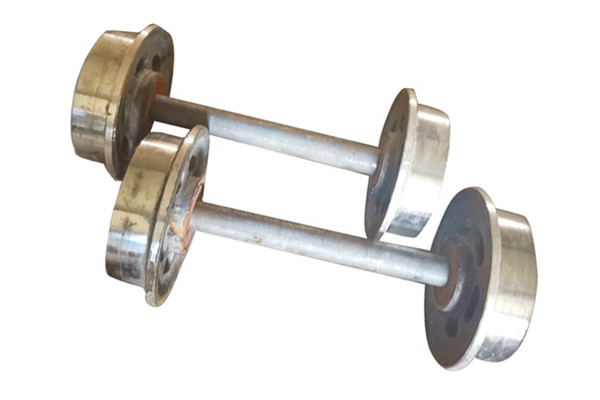

Our flanged wheels are available as single and double flanged wheels.

KR-547 Double Flange Industrial Wheel

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 8-1/8"

Tread Diameter: 7-1/4"

Safe Working Load: 8,500 lbs

KR-547-W Double Flange Industrial Wheel

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 8-1/8"

Tread Diameter: 7-1/4"

Safe Working Load: 6,500 lbs

KR-561 double flange industrial steel wheel

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 9-1/4"

Tread Diameter: 8"

Safe Working Load: 10,500 lbs

KR-562 double flange industrial steel wheel

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 9-1/4"

Tread Diameter: 8"

Safe Working Load: 10,500 lbs

KR-564 industrial steel wheel double flange

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 9-1/4"

Tread Diameter: 8"

Safe Working Load: 14,000 lbs

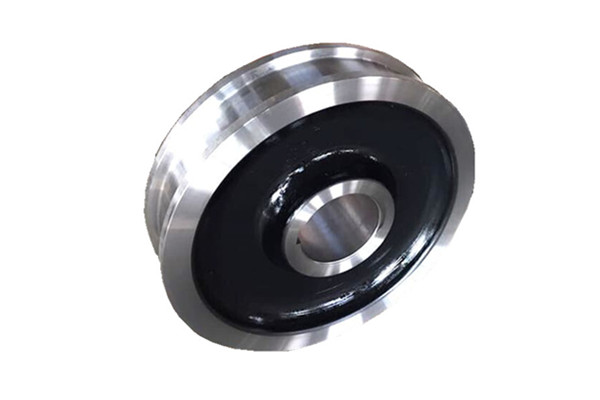

KR-676 industrial steel wheel

Material: Cast Steel ASTM A915, Grade SC1045

Flange Diameter: 12-1/2"

Tread Diameter: 11-1/2"

Safe Working Load: 5,000 lbs

KR-688-A double flange industrial steel wheel

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 12-1/2"

Tread Diameter: 11-1/2"

Safe Working Load: 6,000 lbs

KR-688-H Double Flange Steel Industrial Wheel

Material: Cast Steel ASTM A915, Grade SC1040

Flange Diameter: 12-1/2"

Tread Diameter: 11-1/2"

Safe Working Load: 6,000 lbs

KR-548-M machined double flange wheel

Material: ASTM A29 Steel, Grade 1045

Flange Diameter: 8-1/8"

Tread Diameter: 7-1/4"

Safe Working Load: 8,500 lbs

KR-562-M Machined Double Flange Industrial Wheel

Material: 1040 steel

Flange Diameter: 9"

Tread Diameter: 8"

Safe Working Load: 10,500 lbs

KR-564-M Machined Steel Industrial Wheel

Material: 1040 steel

Flange Diameter: 9"

Tread Diameter: 8"

Safe Working Load: 14,000 lbs

KR-686-M Machined Steel Industrial Wheel

Material: Machined 1040 Steel

Flange Diameter: 14"

Tread Diameter: 12"

Safe Working Load: 60,000 lbs

Contact us

Please contact us for more information and quotations.

Inquiry Now